The Full Overview to Membrane Switch Innovation and Its Applications

The Full Overview to Membrane Switch Innovation and Its Applications

Blog Article

Recognizing the Performance of Membrane Layer Switches Over for Interface Gadget

The functionality of membrane layer switches over stands for a significant advancement in individual interface layout, incorporating effectiveness with visual convenience. As markets progressively prioritize customer experience, understanding the nuances of membrane layer button modern technology becomes essential.

What Are Membrane Switches?

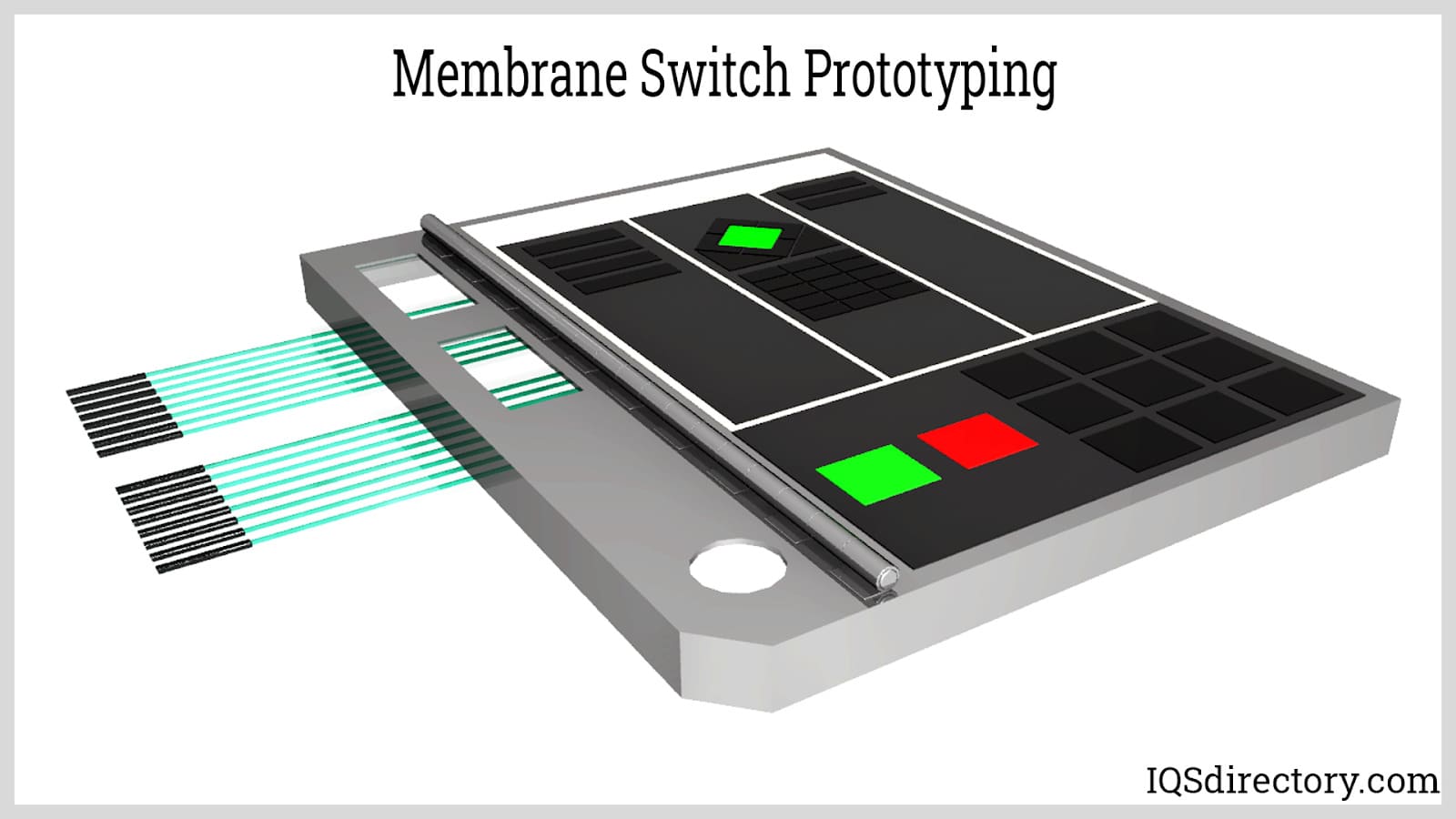

Membrane layer buttons are innovative user interface tools that help with user communication with digital devices. These versatile elements contain several layers, consisting of a graphic overlay, spacer, and a printed circuit layer. The layout enables a smooth assimilation into numerous digital tools, improving both the visual and functional aspects of interface.

Membrane layer switches are generally used in a wide variety of applications, from house home appliances to commercial machinery and medical gadgets. Their building usually features a slim account, making them an optimal selection for portable layouts. The tactile comments provided by these switches can be crafted to satisfy specific individual preferences, making sure effective communication between the individual and the tool.

Toughness is an additional considerable advantage of membrane layer buttons, as they are resistant to dust, wetness, and chemicals, which improves their lifespan in requiring environments. Additionally, these buttons can be customized in terms of shape, size, and graphic design, allowing for branding and user-specific attributes. On the whole, membrane layer switches represent a functional option for improving user experience in digital tools, incorporating capability with aesthetic charm in a reliable manner.

How Membrane Switches Job

Operating on a simple concept, membrane switches over use a split building to sign up customer input efficiently. Each button is composed of multiple layers, including a published circuit layer, a spacer layer, and a top visuals layer, which are developed to collaborate seamlessly. When a user presses the top layer, it compresses the spacer layer, bringing the conductive elements of the circuit layer right into call with each various other.

This call develops a shut circuit, signaling the tool to carry out a specific feature. The layout enables for numerous configurations, consisting of responsive feedback, which can improve the user experience by providing a physical sensation upon activation. The materials utilized in membrane buttons commonly include adaptable substrates, such as polyester or polycarbonate, which ensure resilience and durability versus deterioration.

Key Advantages of Membrane Buttons

Another considerable advantage is their compactness. Membrane layer buttons are slim and lightweight, which enables makers to conserve room in their tools without sacrificing capability. This attribute is especially useful in applications where weight and volume are vital factors to consider.

In addition, membrane buttons are resistant to dirt, moisture, and chemicals, enhancing their sturdiness. This durability extends their lifespan and minimizes the requirement for regular replacements, causing expense savings over time.

Furthermore, the responsive responses supplied by membrane buttons can be enhanced to improve individual interaction. They can consist of functions such as elevated buttons or distinct clicks, enhancing usability and user experience.

Applications Throughout Industries

Interface tools making use of membrane layer buttons are common in a large array of industries, showcasing their flexibility and capability. Membrane Switch. In the clinical industry, membrane buttons are integral to gadgets such as diagnostic devices and person surveillance systems, where their sturdiness and simplicity of cleaning are crucial for keeping health requirements. Similarly, in the automobile industry, these switches are employed in control panel controls and infomercial systems, offering a sleek and contemporary user interface for customers.

Furthermore, the customer electronic devices sector useful content advantages from membrane layer switches in home appliances and portable devices, where compact layout and easy to use user interfaces enhance individual experience. Industrial applications also leverage membrane changes for control panels in machinery and automation systems, emphasizing their effectiveness and resistance to rough environments.

In the aerospace and protection sectors, membrane buttons are made use of in cockpit controls and equipment, where integrity and efficiency under severe conditions are vital. In addition, the video gaming industry significantly includes membrane layer switches in controllers and game makers, adding to an engaging individual experience. In general, the flexibility of membrane layer changes allows their extensive use throughout numerous fields, highlighting their relevance in modern customer interface layout.

Future Fads in Membrane Layer Switch Over Innovation

Additionally, using sophisticated products, such as polycarbonate and polyester films, is expected to rise, giving improved sturdiness and resistance to ecological stress factors. These materials add to the total durability of membrane layer buttons, making them appropriate for harsher commercial applications.

In addition, the consolidation of clever innovation, including IoT connection, will allow membrane layer switches to interact with various other devices and systems, promoting an extra interactive individual experience. This trend straightens with the growing need for wise devices across different sectors, from healthcare to consumer electronic devices.

Last but not least, modification options are expected to increase, allowing manufacturers to create bespoke solutions tailored to specific user demands and choices. These advancements will position membrane buttons as vital elements in the advancement of interface technology.

Final Thought

To conclude, membrane switches stand for a crucial innovation in interface technology, using a reputable and flexible solution for varied digital site link applications. Their layered construction promotes compact design, while features such as tactile responses boost customer communication. The resilience versus environmental variables additionally strengthens their energy across several sectors. As advancements in material scientific research and touch noticing innovations continue, the capability and applicability of membrane buttons are anticipated to broaden, strengthening their importance in modern digital tools.

Report this page